Best Practice Mould Remediation in Australian Restoration Industry

Mould remediation has become one of the most discussed subjects in today’s restoration sector—and for good reason. Claims are increasing, building designs are changing, and expectations from insurers, hygienists, and occupants are higher than ever.

Mould isn’t just a stain. It isn’t just an odour. And it certainly isn’t a “simple cleanup task”.

It’s a building science problem.

It’s a contamination control problem.

And it requires a trained mould remediation specialist — not guesswork.

This article outlines the fundamentals: what mould is, why it forms, its impact on health and materials, and what correct remediation looks like. We also break down common myths and highlight where ACRA training can take your team from competent to industry-leading.

Understanding Mould: Conditions and Classifications

Mould contamination can be classified into three key Condition levels. These categories are essential for scoping, containment strategy, WHS requirements and insurance decision-making.

Condition 1 – Normal Fungal Ecology

An indoor environment reflecting what is naturally expected—settled spores, fragments, and microscopic traces at normal background levels.

Condition 2 – Settled Spores

An environment where spores have migrated from a contaminated area. There may be early surface traces or dormant fragments, but no established colony.

Condition 3 – Actual Growth

Active, dormant, visible or hidden fungal growth. This is true contamination requiring structured remediation, containment, and verification.

Why this matters:

Classifying mould correctly informs risk, labour requirements, equipment selection, and documentation standards. It also helps insurers understand scope justification.

What Does Mould Look Like?

Mould is deceptive. It may appear as:

Green, black, white, brown or orange spotting

Circular patches or diffuse “dusty” areas

Staining beneath paint or wallpaper

Soft, fuzzy, feathery or velvety texture

No visible growth at all, yet strong odour or elevated readings

When it comes to mould, it is crucial to understand that what you see is rarely the full extent. Moisture mapping and environmental measurement remain essential.

Health Impacts: Why Correct Remediation Matters

High humidity and mould-contaminated environments can irritate the respiratory system and disrupt occupant wellbeing. Symptoms may include:

Eye, nose and throat irritation

Persistent cough or chest tightness

Hoarseness or breathing difficulty

Recurring sinus infections

Headaches and fatigue

Difficulty concentrating

For insurers and restoration companies, these health impacts underline the need for correct containment, PPE, and verification testing—not just visual cleaning.

Why Does Mould Happen?

Mould develops for only one reason: excess moisture. But the source can vary depending on the history of the building, the age, environment etc.

Older Buildings

Historic water damage

Leaking roof tiles, gutters, pipes

Poor insulation causing cold surfaces

Condensation forming inside wall assemblies

Newer, Airtight Homes

Modern construction traps moisture unless ventilation is managed well.

Steam from cooking, bathing, drying clothes

Insufficient exhaust systems

Poor airflow due to energy-efficient design

Inadequate humidity control

Regardless of building age, mould is the result, not the cause.

Correct Remediation: What Professionals Should Be Doing

Professional mould remediation services is not “wiping down”.

It is a structured process built on assessment, building science and contamination control.

1. Identify the Moisture Source

No remediation stops mould unless the moisture problem is fixed.

2. Determine the Contamination Level (Condition 1, 2, 3)

This defines containment size and WHS risk.

3. Establish Containment

Physical barriers

Decontamination zones

Negative pressure

HEPA-filtered air scrubbing

Containment protects unaffected areas—a critical requirement for commercial and insurance-managed work.

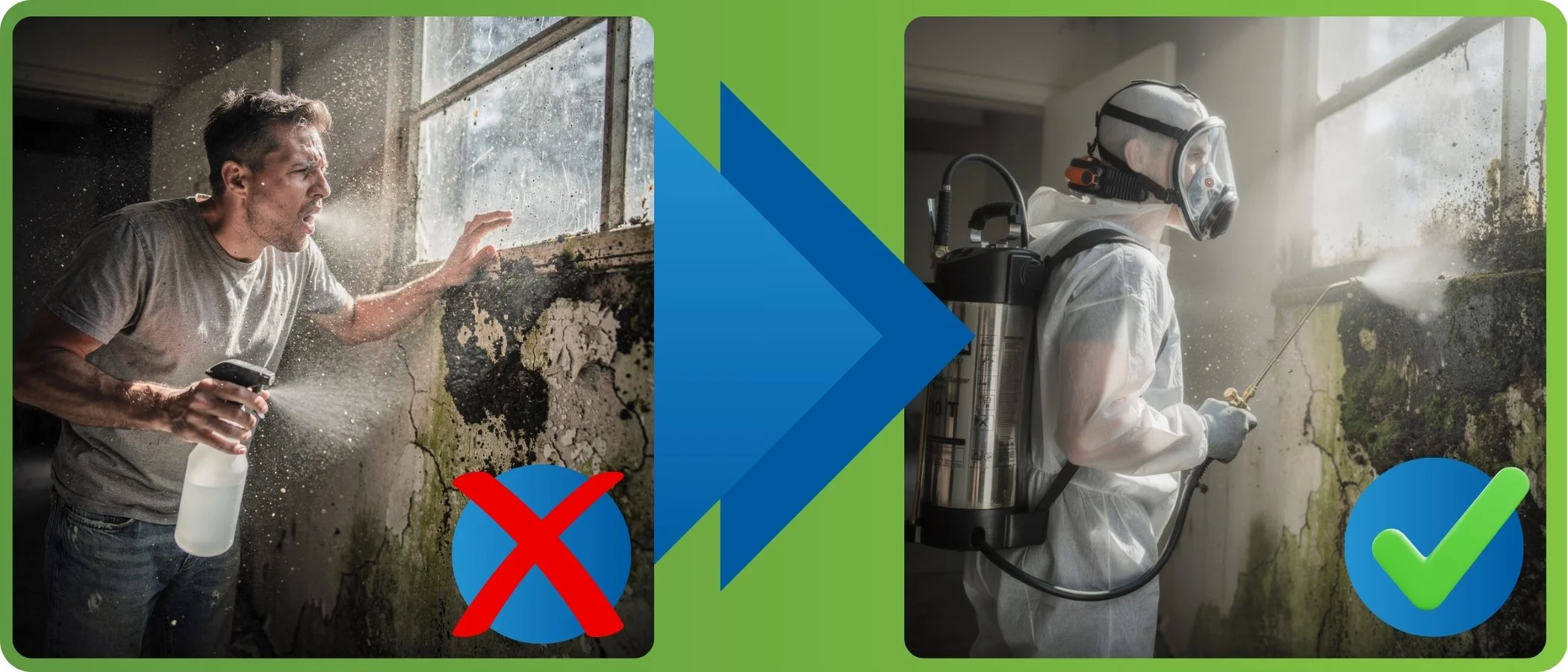

4. Use Correct PPE

Including but not limited to:

Disposable suits

Boot covers

Nitrile or chemical-resistant gloves

P2 or full-face respirators

Eye protection

5. Mechanical Removal & Cleaning

Effective remediation includes:

HEPA vacuuming of surfaces

Removal of unsalvageable porous materials

Mechanical agitation (brushes, pads, scrubbing tools)

Comprehensive surface cleaning

Air cleaning and final wipe-down procedures

6. Appropriate Cleaning Products

Professional-grade solutions used in Australia typically fall into three categories:

Stabilised Chlorine Dioxide (ClO₂) – oxidising, suitable for broad applications

Hydrogen Peroxide Formulations – effective on organic contamination

Quaternary Ammonium Compounds – antimicrobial control for specific applications

What matters is choosing products that don’t leave harmful residues and are fit for purpose based on surface type and WHS requirements.

7. Verification and Clearance

Professionals may use:

Moisture measurements

Particle counting

Surface hygiene verification e.g., A3 testing (ATP/AMP/ADP)

Independent clearance sampling (air or surface testing)

Verification protects the contractor, the insurer, and the occupant.

Breaking the Myths: What We Must Stop Repeating

Myth 1 – “Bleach kills mould.”

Bleach may remove surface staining but does not address hyphae inside porous materials. It also does not stop regrowth.

Myth 2 – “If you can’t see mould, it isn’t there.”

False. Hidden growth is common inside wall cavities, under flooring, behind cabinetry, or within insulation.

Myth 3 – “A chemical spray is enough.”

Professional mould remediation services requires mechanical removal, not just chemical treatment. Spraying alone is not a recognised or defensible method.

Myth 4 – “Mould only happens in old or poorly maintained homes.”

New energy-efficient homes are among the most common sites due to trapped humidity and insufficient ventilation.

Myth 5 – “Air fresheners or odour control solves the problem.”

Odours are caused by microbial volatile organic compounds (mVOCs). Only proper remediation removes the source.

Busting these myths helps professionals communicate clearly, set realistic expectations, and justify correct scope to insurers.

Preventing Mould: Long-Term Control

A mould remediation specialist should guide clients towards long-term prevention:

Maintain indoor relative humidity below 70%

Ensure timber moisture stays below 15%

Improve ventilation in bathrooms, laundries and kitchens

Use mechanical extraction and ensure it vents externally

Consider protective coatings in inaccessible structural areas

Address building defects that trap moisture

Prevention reduces future claims and protects building integrity.

Want to Master Mould Remediation? Train With ACRA

This article provides a broad overview—but the real depth comes from professional training.

ACRA’s mould remediation programs offer:

Hands-on containment setup

Practical HEPA equipment use

Chemical selection and WHS compliance

Moisture detection and building science

Documentation skills for insurers

Real-world case studies and demonstrations

Updates on Australian standards and industry expectations

Whether you’re a technician, supervisor, assessor or insurer, ACRA training ensures you stay aligned with best practice, compliance, and modern building challenges.

Stronger knowledge = safer buildings, better claims outcomes, and a more professional industry.